Blog

Unified Production Management using MineRP

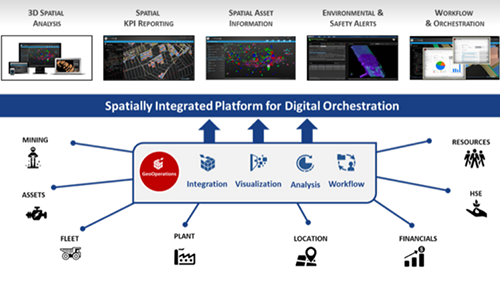

Millisecond Mining is highly dependent on the ability to do real-time planning and digital orchestration of planned activities and tasks between systems, resources and now between intelligent workplace.

To maintain operations at planned levels, efficiently manage events arising from operations, and offer a mature decision support and execution base for operational control by systemically orchestrating execution decisions instead of depending on radio operators in dispatch rooms is not only a challenge, but a requirement for modern mining operations.

The global drive towards mechanization and automation is critically dependent on effective digital orchestration platforms that will enable collaboration, integration, and execution across multidisciplinary organizational silos.

vi-Technologies works with MineRP and its partners like IBM, Wabtec and others who specialize in Digital Orchestration Centers executing on the back of the MineRP enterprise spatial integration platform, and allow mines to orchestrate management activities across multiple control domains, from a central facility. Through integrated digital displays, line-of-business operational control becomes possible as execution is monitored in line with the integrated master business schedule, and rules-based events triggering and work-flow ensure appropriate (where possible automated) response and escalation. Digital Orchestration Centers aim at maintaining steady state execution and minimal disruption through capabilities such as interface-driven re-allocation of resources, re-scheduling, or re-planning activities.

Implementation of a Digital Orchestration Centre supported by a centralized, optimized Master Business Schedule offers a variety of short and long-term benefits:

• Bringing intelligence to the workplace through controlled execution of scheduled (and only scheduled) work, in the right place, with the right resources, at the right time.

• Managing the impact of exceptions and unplanned events on scheduled activities in the shortest time possible by initiating sensitivity-based corrective and prescriptive actions to return to the plan, or generate alternatives that will deliver the same outcome with the minimum impact on the overall plan.

• Replacing radio and telephone as communication devices with automated and digitized processes, supported by up to date and relevant information.

• Enabling control activities aligned to best practice business rules rather than subjective decisions based on personal experience.

• Achieving cross domain execution management in context of inter-domain inter-dependencies.

• Leveraging analytical tools to encapsulate and improve business rules.

Leave a Comment